Design

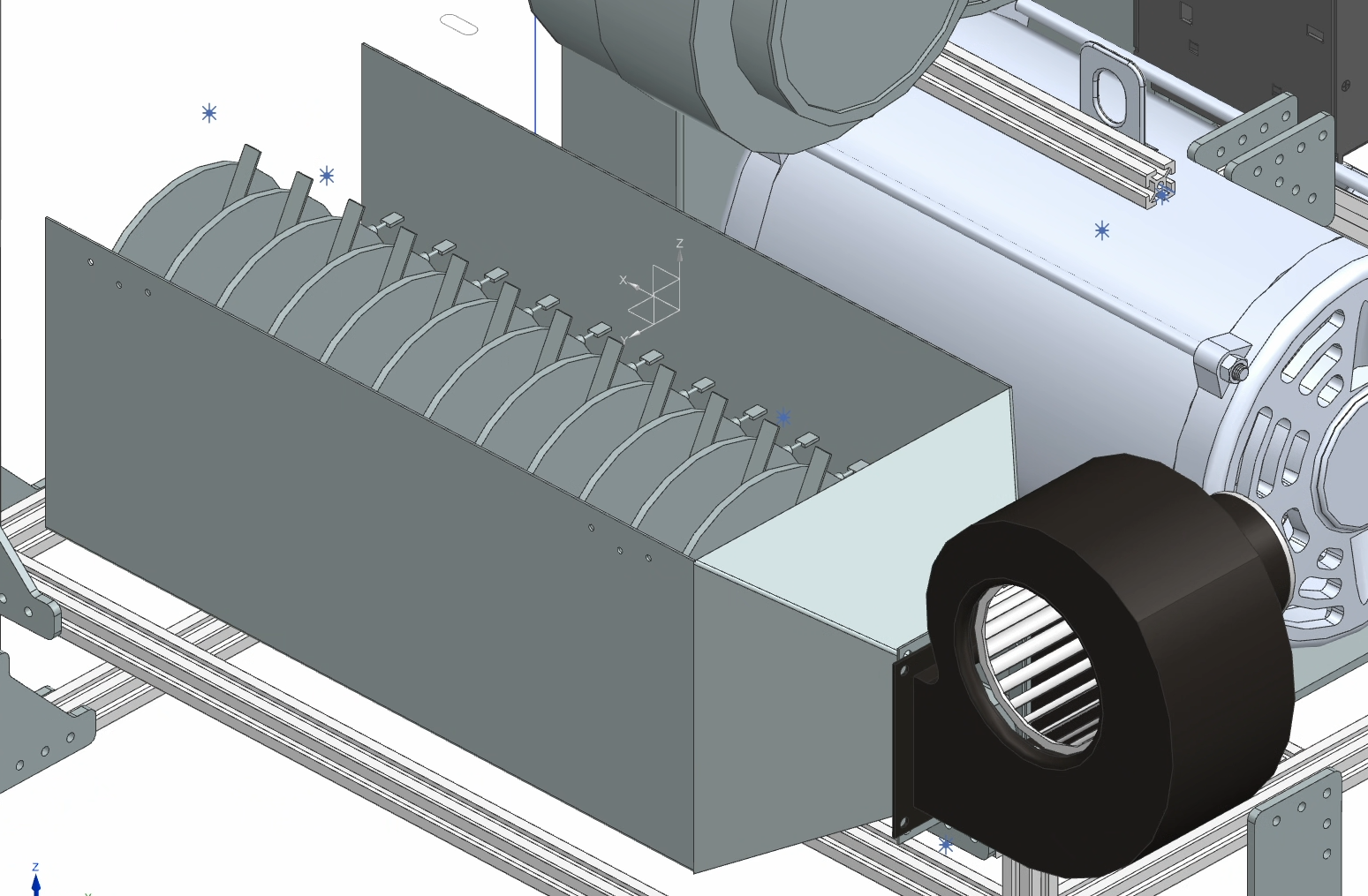

Our car uses a custom CVT, which requires testing and validation for optimal performance, to fully characterize this we built a dynamometer. As a freshman year project, I was tasked with designing a heat shroud for this dyno, which is used to protect the user from the heat generated and improve the thermal performace of the system.

Analysis

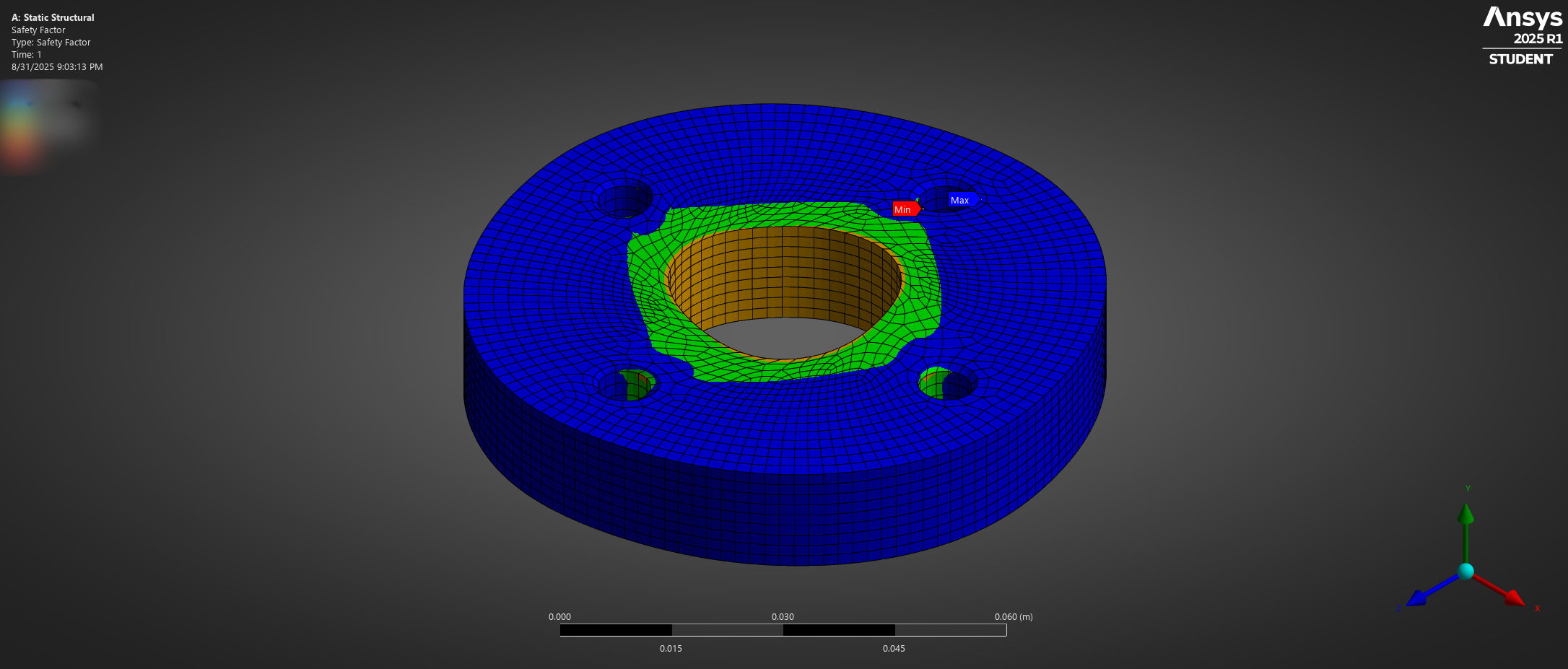

Additionally, as part of my work on the dyno I designed and validated an adaptor between the gearbox and the motor using FEA to ensure safe operation. The adaptor was designed to be a trilobe shape to match the output of the gearbox, and was validated using Ansys to ensure it could withstand the torque loads it would see during operation.

Manufacturing

In order to manufacture the heat shroud, we used a waterjet to cut our sheet metal to the correct dimensions, bent it, and welded it together. The adaptor was manufactured by using a manual lathe to turn the part to the correct dimensions, and then using a CNC machine to achieve the trilobe shape and offset holes into the part.